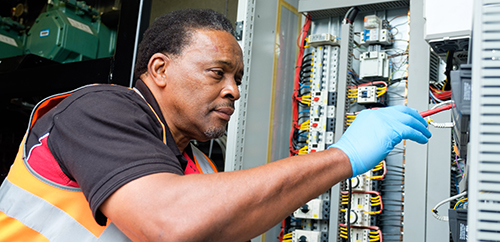

Refrigeration Engineer Case Study – Gartive Henry

Refrigeration engineer, Gartive Henry shares his six year strong experience at Arcus FM and how he has taken advantage of learning, training and development opportunities to deliver a best in practice approach in industrial refrigeration and safety compliance.

How long have you been with Arcus FM?

Six years.

Tell us about your role.

I am responsible for the supply of maintenance and repairs of all refrigeration equipment. I work in the South-East region and look after several Sainsbury’s superstores and petrol stations.

We are the first contact our clients meet, so we do our best to make a good impression.

The store managers are always comfortable with our service and have the confidence in us that we will deliver.

How does your role help to make a difference to our clients?

My priorities as an engineer are to ensure all equipment is functioning at its highest efficiency.

For example, most if not all of our plant equipment is manufactured with electrical Inverters, this device reduces wear and tear along with a reduction in electrical costs.

What learning and development opportunities have you taken advantage of?

Arcus FM provides engineers with all related training at the Arcus Academy. This extensive training helps us excel in our daily tasks and ensures that we follow the latest and best practices in industrial refrigeration – such as using carbon dioxide as a safe, clean and economical alternative to harmful atmospheric gases.

We are fortunate to have highly skilled tutors at the Academy, who see that we strictly adhere to Government regulations, safety compliance, and trained in the safe handling of all relevant gases, ranging from F-gases to flammable hydrocarbons.

Arcus provides all refrigeration engineers with the necessary training needs and equipment to carry out our daily activities, and beyond.

What’s the one thing you love most about working at Arcus FM?

The safety comes first approach, preventing injuries and seeing that we all get home safely.

How long have you been with Arcus FM?

Six years.

Tell us about your role.

I am responsible for the supply of maintenance and repairs of all refrigeration equipment. I work in the South-East region and look after several Sainsbury’s superstores and petrol stations.

We are the first contact our clients meet, so we do our best to make a good impression.

The store managers are always comfortable with our service and have the confidence in us that we will deliver.

How does your role help to make a difference to our clients?

My priorities as an engineer are to ensure all equipment is functioning at its highest efficiency.

For example, most if not all of our plant equipment is manufactured with electrical Inverters, this device reduces wear and tear along with a reduction in electrical costs.

What learning and development opportunities have you taken advantage of?

Arcus FM provides engineers with all related training at the Arcus Academy. This extensive training helps us excel in our daily tasks and ensures that we follow the latest and best practices in industrial refrigeration – such as using carbon dioxide as a safe, clean and economical alternative to harmful atmospheric gases.

We are fortunate to have highly skilled tutors at the Academy, who see that we strictly adhere to Government regulations, safety compliance, and trained in the safe handling of all relevant gases, ranging from F-gases to flammable hydrocarbons.

Arcus provides all refrigeration engineers with the necessary training needs and equipment to carry out our daily activities, and beyond.

What’s the one thing you love most about working at Arcus FM?

The safety comes first approach, preventing injuries and seeing that we all get home safely.

Interested in a career

with Arcus FM?

We offer a wide range of opportunities for those wanting to join us. Check out our careers website via the button below.